How Is The Brittle Layer Formed On The Surface Of Titanium And Titanium Alloys?

2023-08-09

How Is The Brittle Layer Formed On The Surface Of Titanium And Titanium Alloys?

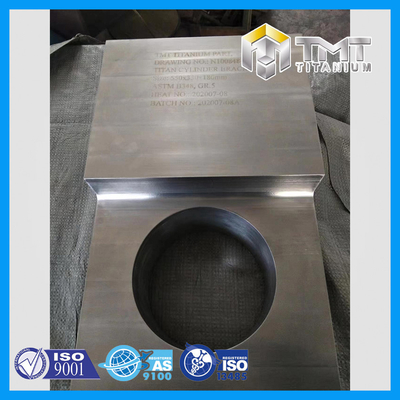

Titanium is an important metal material, titanium alloy has a wide range of applications in aerospace and defense and other fields, mainly used in the manufacture of aircraft parts and engines. High-temperature forging is an important process method for molding titanium alloys. During the high-temperature plastic forming process, a brittle layer is formed on the surface of titanium and titanium alloys. This brittle layer seriously affects the quality of titanium alloy parts.

How is the brittle layer formed on the surface of titanium and titanium alloys? When titanium is exposed to high temperatures, a hard brittle layer, called an alpha layer, forms due to oxygen diffusion into the titanium.

Titanium is a very strong metal and the alpha layer reduces the amount of strain the surface can withstand before cracking. Cracking on the surface of titanium and titanium alloys can lead to the formation of cracks, which ultimately lead to failure of the part. Failure of the part can lead to airplane crashes and injuries. There are three different possible approaches to dealing with alpha layer formation on titanium: prevention, minimization, or removal. The process currently used in the industry to address this issue is removal through chemical milling.

Chemical milling essentially involves immersing the forged product in a container filled with a strong acid, hydrofluoric acid or nitric acid to remove the alpha layer. Currently the chemical milling process is not the ideal solution to the problem because the aviation industry has very strict regulations, which makes chemical milling very expensive. This also exposes the companies involved to legal risks, as in extreme cases, chemical spills can harm employees as well as the surrounding environment. In addition, waste hydrofluoric acid must be disposed of, which raises deeper environmental concerns.

In light of the current progress, several aspects still need to be worked on in depth. First, the mechanism of α-layer generation, aiming to explore the prevention and mitigation of α-layer formation. Second, the effect of different coatings on α-layer, aiming to explore better protective coatings. Third, the evaluation method of α-layer on the surface of titanium and titanium alloys, to accurately determine the depth of the α-layer, and to assist in the formation of the correct chemical milling process.

The study of this problem is conducive to improving the safety of titanium and titanium alloy forgings and the economy of the titanium alloy α-layer removal process.

-

2023-07-29